- Home

- Product Details

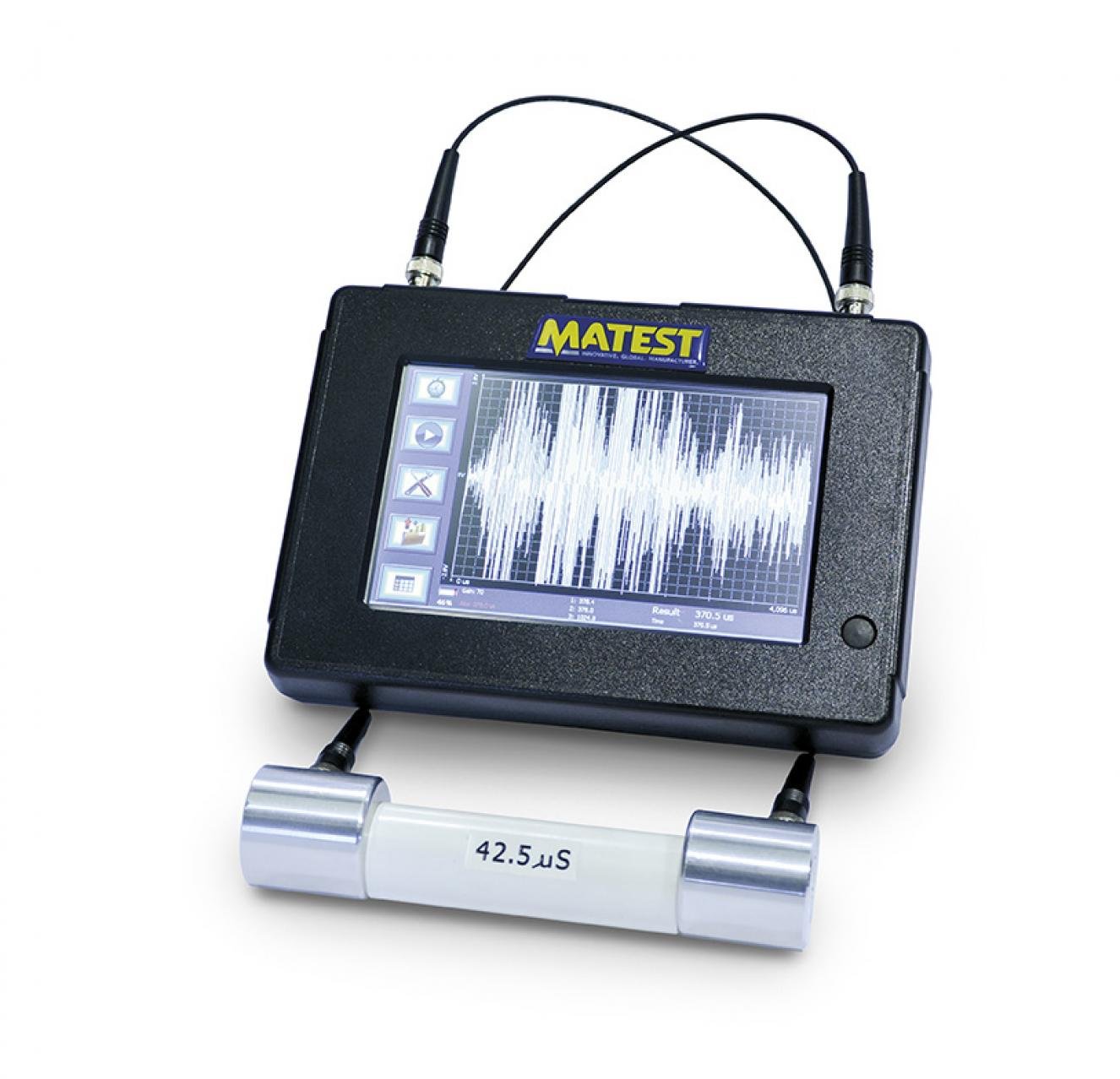

MATEST C372M Ultrasonic Pulse Velocity Tester

Short info :

Ultrasonic pulse velocity tester, high performance with microprocessor for combined ultrasonic and rebound hammer data acquisition and processing.

Wizard Auto 250 KN - Automatic Compression Testing Machines

Description:

The device is suitable to execute various measurements regarding the mechanical properties and physical conditions of different materials. In particular, based on the known data (for example the distance between the probes) it is possible to measure the ultrasonic impulse speed inside different materials.

This information allows us to suppose a possible status of conservation of the concrete (or other materials) and deduce the mechanical properties.

Features:

MAIN FEATURES

- Touch screen LCD, 7’’, 800x480 pixel

- User-friendly interface

- 16 Gb memory

- Time measuring from 0 to 9999.9 µs

- Resolution 0.1 µs

- Possibility to combine the ultrasonic measurement with the rebound index (SonReb method)

The device includes a touch-screen display with ports for the connection of two probes, two 55 kHz probes with connecting cables, a calibration cylinder, a tube of grease, a carrying case with a handle and a shoulder strap.

ULTRASONIC TESTS Some of the tests that can be performed with C372M are:

- Measuring the flight time between the two probes

- Measuring the speed of the signal if the distance between the probes is known.

- Determination of the distance between the probes if the speed is known.

- Young modulus if the Poisson ratio, the density and the distance between the probes are known.

Standards:

- ASTM C597

- EN 12504-4

Specifications:

Combined ultrasonic and rebound hammer determination (sonreb method): The C372M ultrasonic tester houses an integral data logger for data acquisition, processing and store of rebound hammer values. The acquisition of the rebound values is performed with manual or automatic mode.

As for the Automatic mode, the digital Matest test hammer mod C386M is directly connected to the ultrasonic tester through a cable. The measured rebound values are automatically transmitted to the C372M tester.

The combined test allow to rectify different inaccuracies that are typical of the simple rebound hammer test, and obtaining estimates on the compressive strength of the concrete, that cannot be obtained with the ultrasonic test, granting high accuracy and reliability of the results.

The standard appliance includes:

• Instrument in basic configuration (x-scale 400MHz, 64MB Flash Memory, 64 MB Ram) in a practical and elegant palmer container.

• Two 55 kHz probes with connecting cables.

• Calibrating cylinder and contact paste

• Strong anti shock case holding the instrument and the accessories.

• Battery pack Li-Ion 11,1V 3000 mA/per hour

• External feeder 230V/24V and battery charger

Dimensions: 400x300x180 mm.

Weight: 5 kg.

Products:

Ultrasonic pulse velocity tester, high performance with microprocessor for combined ultrasonic and rebound hammer data acquisition and processing.

The appliance allows measuring:

- Ultrasonic impulse speed inside the material, by knowing the distance between the probes;

- distance between the probes, by knowing the speed of the ultrasonic impulse to go through the tested material;

- required time by the ultrasonic impulse to go through the tested material.

- Young’s modulus, by knowing the distance between the probes and the density of the tested material

- Crack depth

- Zero calibration with depuration of the time for the impulse to go through the probes. Calibration of a defined time value.

- Advanced function for research purposes:

Selection of the transmission frequency of the impulse.

Selection of the impulse amplitude.

Possibility to use the instrument with two exponential probes, or with one standard probe and one exponential probe.