- Home

- Product Details

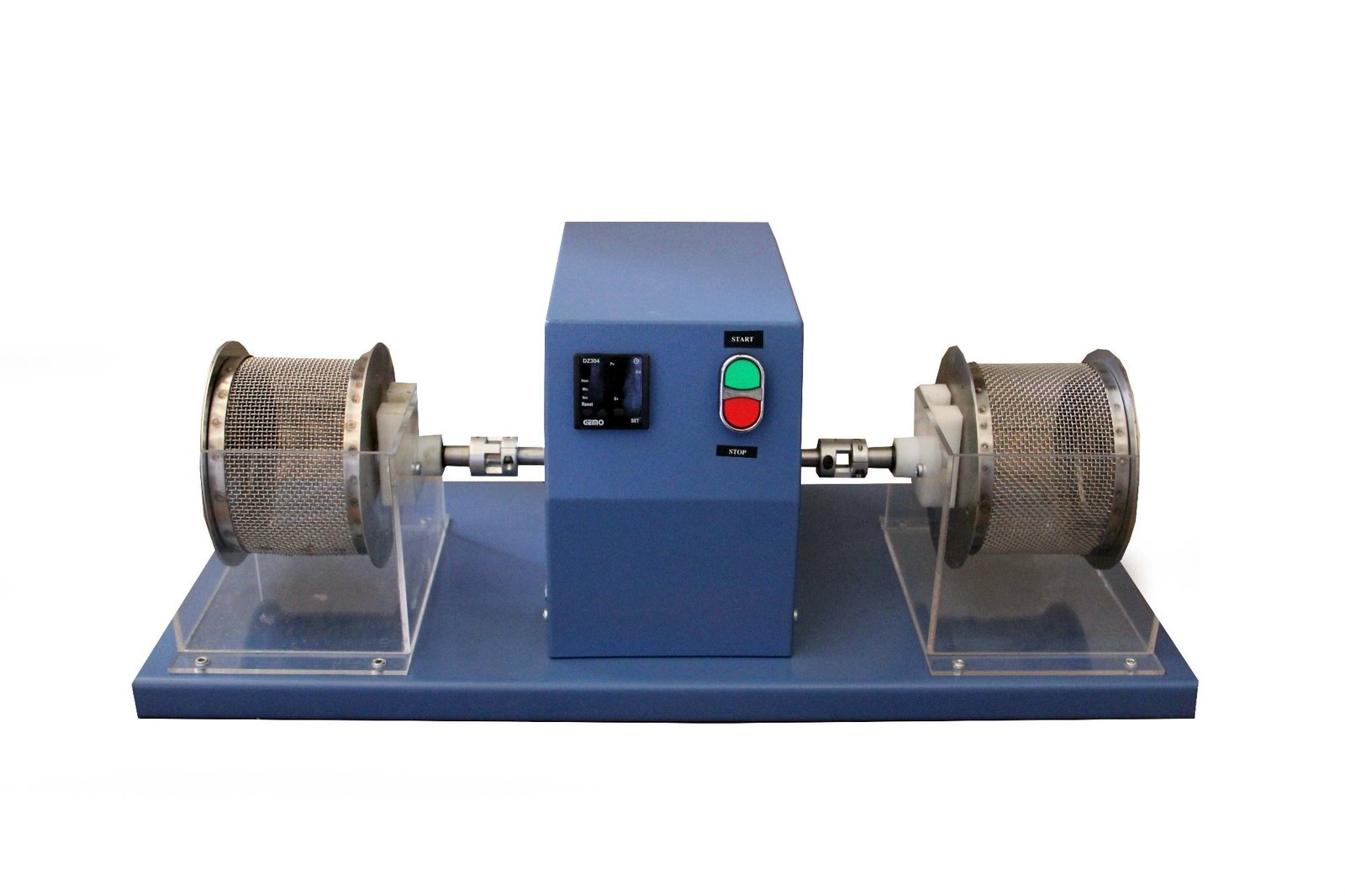

Slake Durability Test Apparatus

Short info :

The Slake Durability Test Apparatus is a specialized laboratory device used in geology and geotechnical engineering to evaluate the durability of weak or weathered rocks, especially shales, mudstones, and siltstones, when subjected to wetting and drying cycles. This test helps assess how a rock sample will perform under natural weathering conditions, particularly where repeated wetting and drying can cause disintegration.

Wizard Auto 250 KN - Automatic Compression Testing Machines

Description:

The Slake Durability Test Apparatus is a specialized laboratory device used in geology and geotechnical engineering to evaluate the durability of weak or weathered rocks, especially shales, mudstones, and siltstones, when subjected to wetting and drying cycles. This test helps assess how a rock sample will perform under natural weathering conditions, particularly where repeated wetting and drying can cause disintegration.

Features:

Dual Stainless-Steel Drums

- Cylindrical drums made of corrosion-resistant stainless steel.

- 2 mm mesh to allow fine particles to escape while retaining larger fragments.

- Conforms to ASTM D4644 and ISRM standards.

Durable Rotating Mechanism

- Equipped with a motorized drive for consistent drum rotation.

- Standard rotation speed: 20 ± 2 revolutions per minute (rpm).

- Smooth, vibration-free operation ensures uniform agitation.

Water Bath / Trough

- Provides partial immersion of drums during testing.

- Constructed of non-reactive materials to resist corrosion.

- Ensures accurate simulation of natural wetting conditions.

Time-Controlled Operation

- Integrated timer system for automated control of test duration.

- Typically set for 10-minute cycles, as per standard test protocols.

Compact & Rigid Frame

- Robust frame to withstand repetitive motion and ensure long-term durability.

- Often fitted with anti-slip rubber feet or mounting options.

Standards:

- IS:10050-1981

- ASTM D 4644

Specifications:

- This test method has been developed to assess the deterioration of rocks over a period of time when subjected to water immersion.

- Slake durability is a simulated weathering test to determine abrasion resistance during wetting and drying cycles of shale and similar soft rocks as used in embankments and other construction-related applications.

- Samples are alternately tumbled in mesh drums through a water medium and oven-dried for two cycles. The percent loss of mass is referred to as the slake durability index.

- Slake durability apparatus consists of a motorized drive unit which is mounted on a baseplate and which can rotate two or four drums at a speed of 20 r.p.m.

- The tank assemblies are filled with water to a level 20mm below the drum axis.

- The test drums are manufactured from 2.00 mm mesh, 140 mm dia. X 100 mm long.

Products:

- Cylindrical stainless-steel drums with 2 mm mesh

- Corrosion-resistant container to hold distilled or deionized water

- Sample Preparation Tools

- Tongs or Heat-Resistant Gloves

- Instruction Manual