- Home

- Product Details

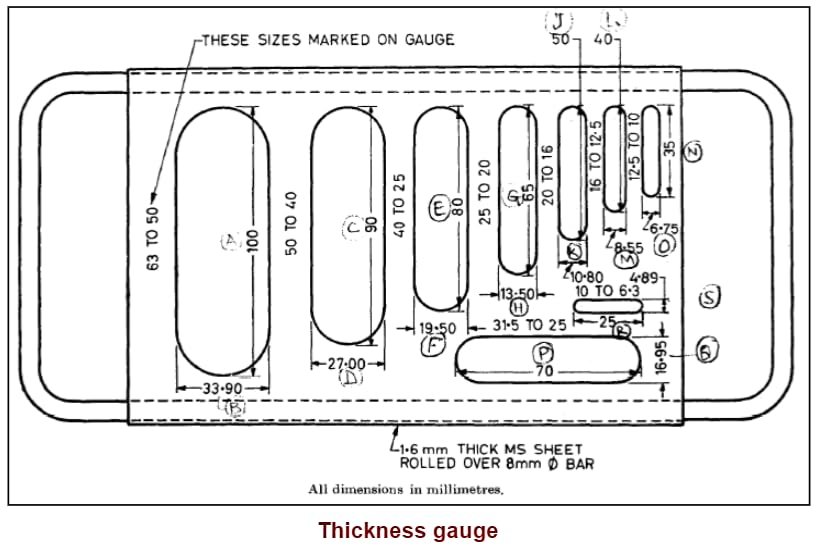

Flakiness Gauge (Thickness Gauge)

Short info :

The Flakiness Gauge, also known as the Thickness Gauge, features a slotted stainless steel gauge that allows for quick and easy manual testing of particles from the seven sieve fractions. This process helps determine the flakiness index of the material being tested.

Wizard Auto 250 KN - Automatic Compression Testing Machines

Description:

Determination of Flakiness Indices of Aggregates (According to British Standards)

The flakiness and elongation characteristics of coarse aggregates are assessed in accordance with the British Standard classification system. These shape parameters are critical in evaluating aggregate suitability for use in construction, particularly for surface layers and high-performance concrete.

Aggregates are initially sieved into seven standard size fractions ranging from 63 mm to 6.3 mm. Each size fraction is tested separately to ensure accuracy and consistency in the evaluation.

- Flakiness Index: Determined using a Thickness Gauge. For each size fraction, individual particles are assessed to identify those with a thickness less than 0.6 times the mean sieve size. The flakiness index is expressed as the percentage by mass of such particles relative to the total mass of the sample for that fraction.

The final indices may be presented for individual fractions or as a weighted average across all tested fractions, depending on project requirements or specified standards.

Features:

Determination of Flakiness Indices of Aggregates (According to British Standards)

The flakiness and elongation characteristics of coarse aggregates are assessed in accordance with the British Standard classification system. These shape parameters are critical in evaluating aggregate suitability for use in construction, particularly for surface layers and high-performance concrete.

Aggregates are initially sieved into seven standard size fractions ranging from 63 mm to 6.3 mm. Each size fraction is tested separately to ensure accuracy and consistency in the evaluation.

- Flakiness Index: Determined using a Thickness Gauge. For each size fraction, individual particles are assessed to identify those with a thickness less than 0.6 times the mean sieve size. The flakiness index is expressed as the percentage by mass of such particles relative to the total mass of the sample for that fraction.

The final indices may be presented for individual fractions or as a weighted average across all tested fractions, depending on project requirements or specified standards.

Standards:

- IS:2386 (Part 1) – 1963

- BS:812 (Part 105)

- ASTM D4791

Specifications:

Flakiness Gauge (Thickness Gauge) – Aggregate Shape Testing Tool

Product Overview:

The Flakiness Gauge, also known as a Thickness Gauge, is a precision testing instrument used to determine the Flakiness Index of coarse aggregates in accordance with BS 812-105.1 standards. This test is essential in evaluating the shape characteristics of aggregates, ensuring compliance with specification limits for use in concrete, road construction, and other civil engineering applications.

Key Specifications:

- Material: Durable powder-coated or stainless steel body for corrosion resistance and long-term use

- Slot Sizes: Seven standard slots corresponding to aggregate sieve sizes:

- 63 mm – 50 mm

- 50 mm – 40 mm

- 40 mm – 31.5 mm

- 31.5 mm – 25 mm

- 25 mm – 20 mm

- 20 mm – 16 mm

- 16 mm – 10 mm

- 10 mm – 6.3 mm

- Conformance: Complies with BS 812: Part 105.1

- Application: Suitable for aggregates ranging from 63 mm to 6.3 mm

- Purpose: Identifies flaky particles—those with a thickness less than 0.6 times their mean sieve size

- Usage: Used in laboratories for quality control and aggregate classification

- Packaging: Supplied with an instruction manual and a protective case (optional)

Typical Users:

Civil engineering labs, road construction quality control teams, concrete material suppliers, and academic institutions.

Products:

Determination of Flakiness Indices of Aggregates (According to British Standards)

The flakiness and elongation characteristics of coarse aggregates are assessed in accordance with the British Standard classification system. These shape parameters are critical in evaluating aggregate suitability for use in construction, particularly for surface layers and high-performance concrete.

Aggregates are initially sieved into seven standard size fractions ranging from 63 mm to 6.3 mm. Each size fraction is tested separately to ensure accuracy and consistency in the evaluation.

- Flakiness Index: Determined using a Thickness Gauge. For each size fraction, individual particles are assessed to identify those with a thickness less than 0.6 times the mean sieve size. The flakiness index is expressed as the percentage by mass of such particles relative to the total mass of the sample for that fraction.

The final indices may be presented for individual fractions or as a weighted average across all tested fractions, depending on project requirements or specified standards.